With no power, there is no light. The electrical systems in a building are often those that weave the invisible threads of energy, giving life to the technological heartbeat within.

Sign up to newsletter

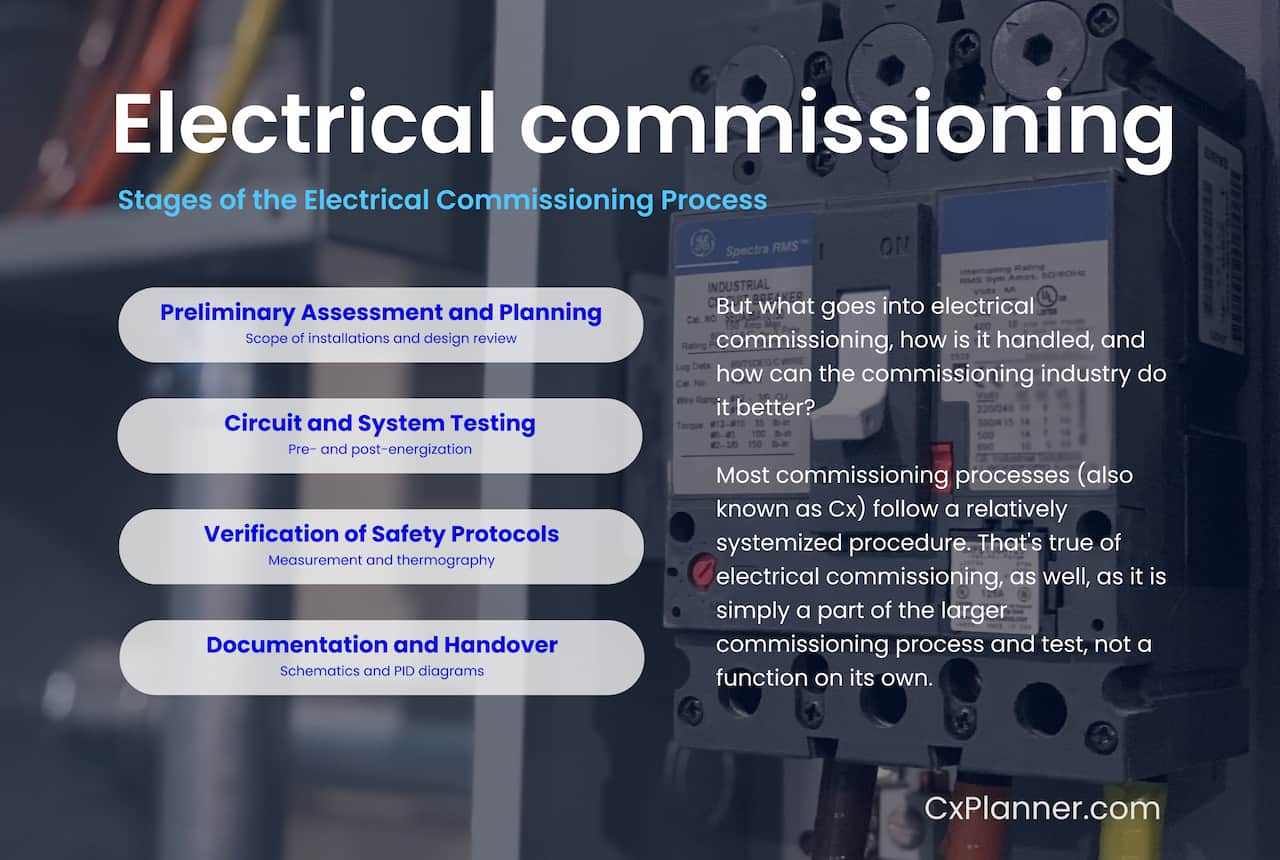

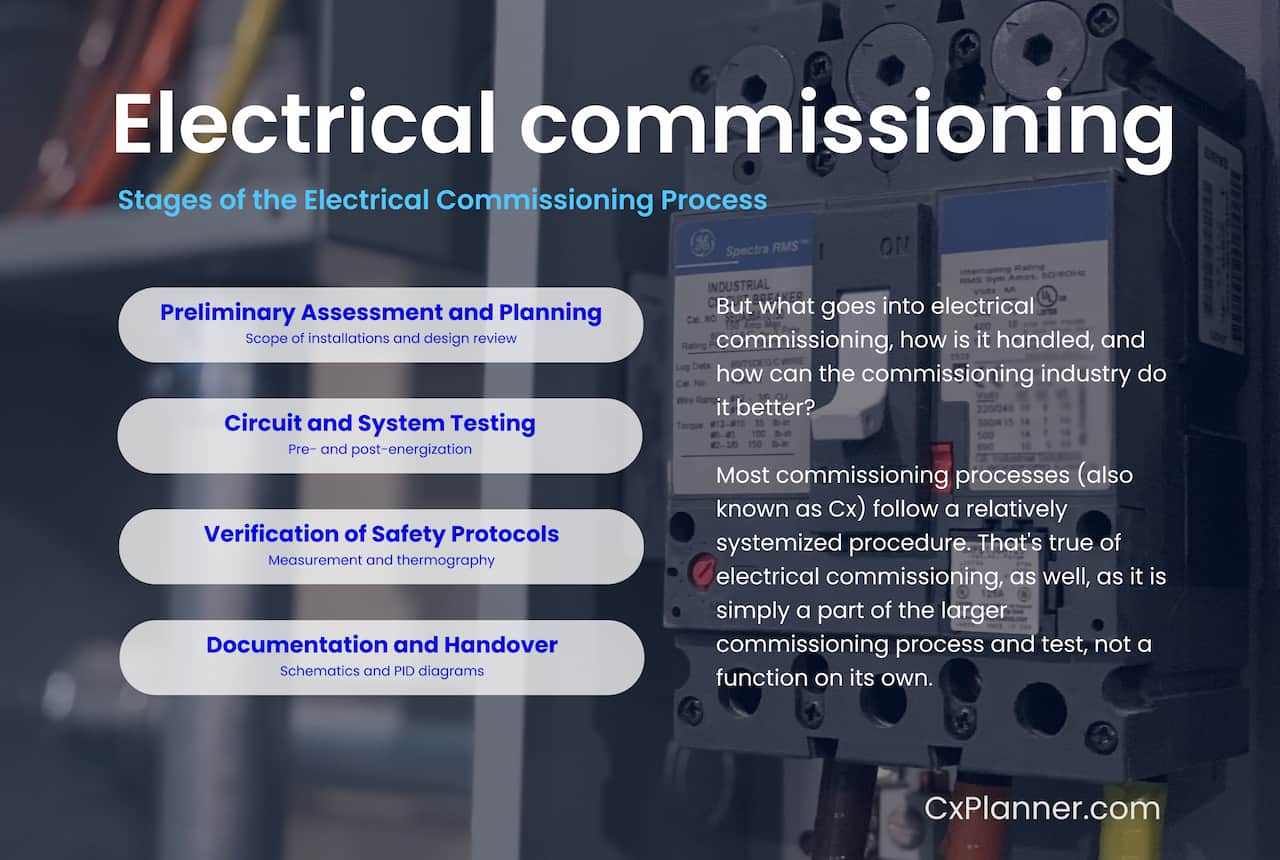

But what goes into electrical commissioning, how is it handled, and how can the commissioning industry do it better? This guide on electrical testing will explain.

Most commissioning processes (also known as Cx) follow a relatively systemized procedure. That's true of electrical commissioning, as well, as it is simply a part of the larger commissioning process and test, not a function on its own. However, the following sections will explain the electrical commissioning component of a Cx test.

The first step in performing commissioning of an electrical installation is the initial assessment of the system or components and the planning of the Cx process. The commissioning agent (CxA) will investigate and review the equipment and system schematics and instrumentation diagrams (PID). The CxA uses these documents to ensure they understand how the current is running in the system and how it integrates with other systems and equipment (power supply). This also allows them to determine what needs to be tested and verified to be working.

For example, these documents will highlight equipment and components such as fuses and their sizes, breakers, cables, parallel usage, and more. With these documents to review, the CxA knows what to look for to ensure everything is installed to spec. Also, if there are any high voltage (HV) systems, they're able to design the entire process to ensure safety.

The CxA also assembles a commissioning team. The Cx team consists of engineers, contractors, subs, and building maintenance personnel. These members will be responsible for particular tasks during the commissioning process.

After assembling the team and a plan, the next step is circuit and system testing. The goal is to verify that the system is working properly, safely, and according to the owner's project requirements (OPR).

There are a few stages to circuit and system testing. These include commissioning activities during the pre-energization, energization, and post-energization phases.

One of the most important aspects of electrical commissioning is the verification of safety protocols. This part of electrical commissioning takes the testing beyond the operation of the electrical system and ensures that the safety protocols in place work from a practical standpoint.

The thermography of switchboards is a core part of the verification of the safety protocols. The thermography is often also a part of the load test during the circuit and system testing, but will also be performed as a standalone activity. When performed as a standalone activity:

This entire process has to be documented by the Cx team. This allows the team to put together a plan for fixing deficiencies and provides a helpful baseline for efficient operation. But with so many tasks involved, it's best to use commissioning software like CxPlanner, as it can help keep all of the tasks organized and make assigning them to the individual team members straightforward.

The documentation can normally be divided into:

All of this data is collected and reviewed. Once all of the systems, switches, fuses, and other electrical components are verified to be in working order, the Cx process is prepared for handover. This phase is when CxA ensures that the electrical system meets the owner's project requirements and operates as it should.

With so many tasks associated with electrical commissioning, it's important to break the project into roles. Each role will have its own tasks to perform, making a large-scale commissioning project easier to tackle.

The commissioning agent focusing on the electrical testing will often be an individual who has previously worked within the electrical field. That could be within low voltage, high voltage, BMS systems, etc.

The person's competences must be chosen based on the electrical systems included in the specific commissioning job. Some of the needed activities for this person is:

There are more responsibilities, as well. For example, the CxA is responsible for coordinating communication between all of the members of the Cx team. CxPlanner can streamline this, providing a platform for all members of the Cx team to communicate about tasks, deficiencies, schedules, and more.

Since the CxA is responsible for developing and maintaining the OPR, they also develop the Basis of Design (BoD) with the designers. The BoD will ensure that electrical items in the OPR, such as requirements for breakers or the over-dimension of cable trays, are replied to directly in the BoD.

During the detailed design phase, the CxA will start to develop test programs and test plans for the electrical installations. It's wise to involve the designer in this development since their knowledge of the system can highlight potential errors and critical points in the test.

With advancements in modern electrical systems, it only makes sense to embrace technology in the tools we use to commission them. The benefits of using CxPlanner commissioning software are many: